|

Mastfoot blocks

The mastfootblocks on a

new 370 is way under dimensioned wich we learned one calm summer night.

It is onlu pure luck that the blocks did not fail earlier when we sailed

the boat home. At that time there would been serious problems to solve

the matter. |

1. One evening at Norrviken in Runmarö we noticed that there was mouse poop on the deck which was really strange! |

2. The mouse poop was hard, sharp and of plastic... and it did not smell! |

3. It showed that the ball bearings in the block had been

shreded to pieces. No wonder that we had some trouble to hoist

the main sail lately. |

4. The 72 millimeter block we had fitted on the jib was removed and had to act as temporaly solution. |

5. Since there were no forks on the block we had to use double

schackles to fit the block to the mast foot. Later on when we

sailed to finland we found out that there was blocks with a fork

but that the sprint was of 8 mm steel instead of the 6 mm we

needed due to the holes in the pins in the mast foot. so this

solution turned to be permanent. |

6. The new solution showed to be a short solution as it was not strong enough. One day when we hoisted the main sail we heard a loud bang from somewhere when we still had 5 meters left to hoist up the main sail. We went up on the deck just to see that... |

7...the schakle we fitted on the block had opened from the threads. This resulted that the block got a different angle to the deck organizers below the cover plates on the deck... |

8...and pulled away the little supporting strut from its glueing

on both the bottom and top side so the strut dissapeared some

where far-far-away under the cover plates. It took us couple of

days before we realized that the strut was gone and before we

foudn it so we could fish it up with some steel wire we had as

spare part. It was pute luck that we did not have to stand on

the top of the opening, otherwise it would cracked. |

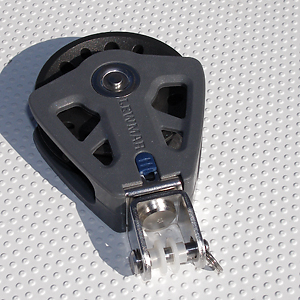

9. We made some calls to our dealer Bryggan i väst and explained to them our re-occuring problem. They told us that Lewmar had rebuilt a 72 mm block so it would work better with the mast foot pins on our rigg. Bryggan sent us one new block immediately so we got it the next day! Well done indeed! |

10. What they had

done was to put two plastic bushings in the fork that

would compensate for the sprint that was only 6 mm instead of

8mm, as it is on all 72 mm mast foot block. The pin is also

longer than the regular 6 mm pin for 60 mm blocks. It should be

a little longer in order to be able to insert the locking ring

without difficulty. An alternative is to cut the plastic a bit

outside the fork. |

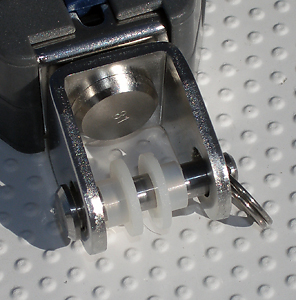

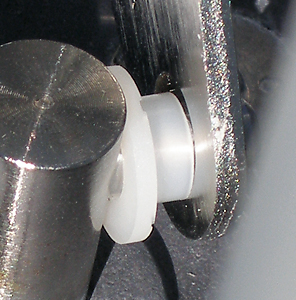

11. Here you can see the plastic bushings when they are not inserted in the forks. |

12. Detailed picture of the bushings. |

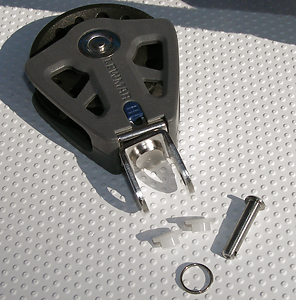

13. The kit that makes it possible to use the 72 mm blocks as mast foot blocks. |

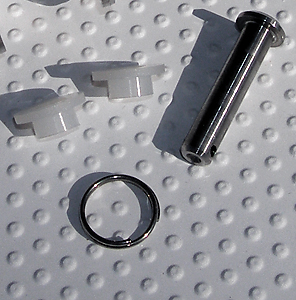

14. Detailed

picture of the bushings, sprint and locking ring. |

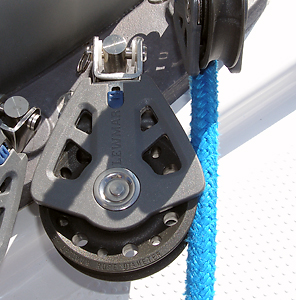

15. The block in its place again. |

16. But it showed that there was a glitch that allowed the the block to move. |

17. The glitch was so big that the plastic bushings did not stay in their places. |

18. If you gonna use this solution something is definetly going to break! |

19. Here you can see that the plastic bushings will not go back to their holes again and will be damaged later on. |

20. After a suggestion from a fellow Hanse 370 sailer, we added two stainless steel sheaves (inner measure 6,4 mm) on both sides of the plastic bushings. Now the glitch is gone, everything works as it should. one agian a solution that should been standard from the shipyard. Thanks for the suggestion Peter P! |

21. The block on its place once again. Later on all the blocks were changed from the dealer to same modell of block. |

|

Material: Lewmar 72 mm masfoot block. Rebuild-kit with 6 mm sprint, locking ring and plastic bushings. Completed with two stainless steel sheaves with the measures: 6,4 x 18 x 1,5 mm.

Place of

purchase:

|

|

|

|

|