|

Fixing the Yanmar SD50

clutch slipping problem (Clutch Maintenence) UNDER CONSTRUCTION

|

|

|

Please watch these videos on Youtube before you start working with the clutch

as the films gives you a better visual description for some aprts of our

text below.

|

|

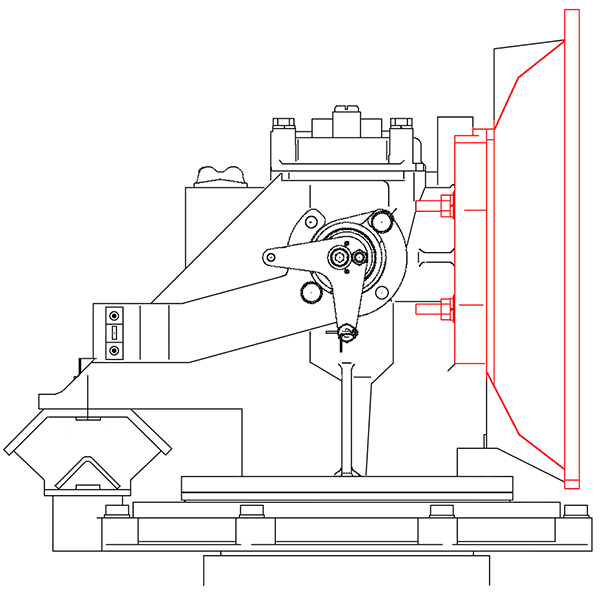

A general overwiev of the xxx part of the SD50 |

|

1. Removing the clutch oil |

|

2.Removing the gear casing cover 2b. Lift the cover carefully as there is a o-ring inside. Be also carefull with the o-ring so you dont loose it or damage it. 2c. There might also be a shimm underneath (on S/y Älva there was no shimm). Don't lose the shim and dont bend it. You can also just let the casing cover stay in its place after unscrewing the bolts as you will now move to next step and its better if you protect the clutch from geting dirty.

|

|

3. Releasing the shift leaver Tools: 13 mm socket wrench mark with a marker pen so you know where to re-aligne the sifter theres is a spring inside so the lever is popping out open the two bolts, be carefull that you dont drop the lock washers. These two blots are slightly shorter than on the cover so its easy to know which belongs to whic part if you happend to mix them. Look at the gear shifter inside and be sure that you know which side is to the front and which is to the aft .See Film 3 at time 18:10. |

|

4.Moving the axis from the bellhouse

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|